CAPABILITIES:

GO BEYOND THE STANDARD…

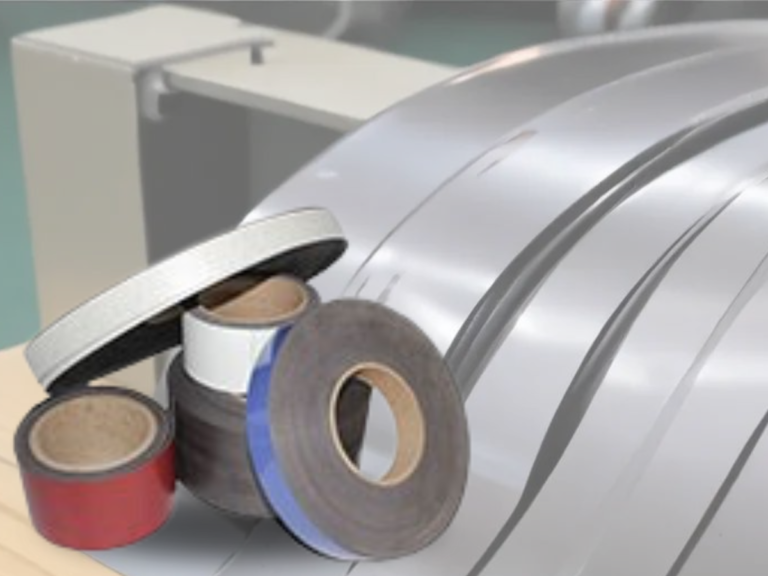

Many of our manufacturing and commercial customers require adhesive magnetic strips in non-standard widths. We custom cut or slit tapes from 3/8″ up to 58″ to meet those application requirements.

We can produce short-run volumes up to trailer loads quickly and competitively priced. With low minimum orders, fast samples, and customization of a variety of adhesive products, our experienced staff can assist you in selecting the right adhesive tape for your application and unique projects. Call us today to help choose an adhesive tape that is right for you.

WE CAN SAVE YOU MONEY

By converting jumbo rolls of adhesive tape material into custom shapes, sizes, and configurations, we make it easier and more economical to use.We partner with engineers, purchasing, and logistics departments in an effort to solve problems and design solutions that help our customers gain an advantage in their respective markets.

TIPS FOR PROPER APPLICATION

To ensure the proper performance of your pressure-sensitive adhesive tape on your product, the application process is the key. Improper surface preparation and application can result in short – or long-term challenges.

A few simple tips to remember when applying your adhesive tape are surface preparation, apply pressure, and allow time to cure. Each of these will help ensure proper bonding of the two surfaces.

Always clean the surface(s) of any contaminants including dust, oils, and grease before applying adhesive tapes. This can be done with a clean cloth and if necessary a cleaning solution or solvent to ensure you have removed oils on the surface.

After allowing to dry, apply adhesive magnetic strips with pressure to ensure a tight bond. Pressure helps the adhesive to begin the reaction process of bonding to the surface.

Allow the adhesive tape to cure or dwell for the recommended time for the specific tape. This helps the tape release into the microscopic pores of the surface and create a maximum bond.