How to Choose the Right Neo Magnet for Your Application?

Do you have a project that requires neodymium magnets? Neodymium magnets are known for their incredible magnetic strength and versatility. However, it still requires you

Magnetic assemblies and devices provide high strength at low cost. Combining magnets with steel armatures increases strength dramatically (up to 32 times) by concentrating magnetic flux. An armature can take several forms; a backing plate, channel or cup are common features that provide other functionality in addition to multiplying the attractive force.

Common Magnetic Assemblies uses are:

Download Our Sign Solutions Brochure

Round Base Magnets provide exceptional economy, high holding power and compact designs. The addition of a metal cup to a standard, inexpensive, cylindrical Ceramic Magnet provides a platform for a number of design applications. Several standard sizes are available, and all have a hole in the magnet and the metal cup to accept a handle or other device.

Channel Magnets multiply the attractive force of your magnet by placing it into a metal channel.

This configuration is popular for knife holders, tool holders and similar devices due to the simplicity. Another benefit is the ability to create a large, highly attraction surface using simple, inexpensive components.

Sandwich Magnets are comprised of two pieces of ferrous metal with a magnet in between. The presence of the metal increases the attraction force exponentially. This configuration is frequently used in latches and other things like that.

Ceramic Holding Assemblies resist demagnetization by vibration and electrical fields. They are ideal for use as work holders on welding machines and other equipment with strong demagnetizing fields. Cylindrical Ceramic holding assemblies can be installed by a simple press fit with only a slight reduction in holding values.

Contact us to help select the right magnet for you.

Shielded Magnets are primarily used to supply a holding force in limited areas of steel tools, dies and fixtures. The sheath, acting as an insulator, prevents undue loss of magnetic flux at the magnet pole when inserted directly into steel components. This type of assembly is usually efficient when there is no severe limitation on magnet length. The pull force against a flat steel surface will vary from several ounces to pounds, depending upon magnet diameter and length. Greatest pull is achieved if magnet length is at least 4.2 times the diameter – less pull when length of magnet is reduced.

Contact us to help select the right magnet for you.

Simply complete and submit the online form below and we’ll review your specs and contact you with any questions.

Do you have a project that requires neodymium magnets? Neodymium magnets are known for their incredible magnetic strength and versatility. However, it still requires you

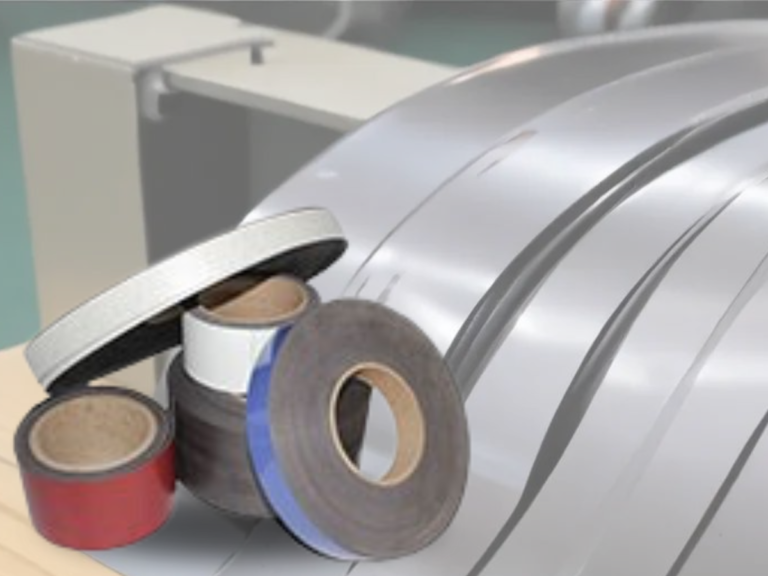

Flexible permanent magnets come with unique properties, making them important for various industries. From healthcare to automotive, and from consumer electronics to renewable energy, the

Strong rare earth magnets are the strongest type of permanent magnets. Thanks to their incredible magnetic fields compared to other types such as alnico or

Our magnet experts will help you get exactly what you need – custom or stock – in record time with great quality at a very competitive price.

Ⓒ 2022 - All Rights Are Reserved