GRADES

Different material grades provide price/performance options. The chart to the right provides summary information; contact us for detailed technical information.

STANDARD SIZES AND SHAPES

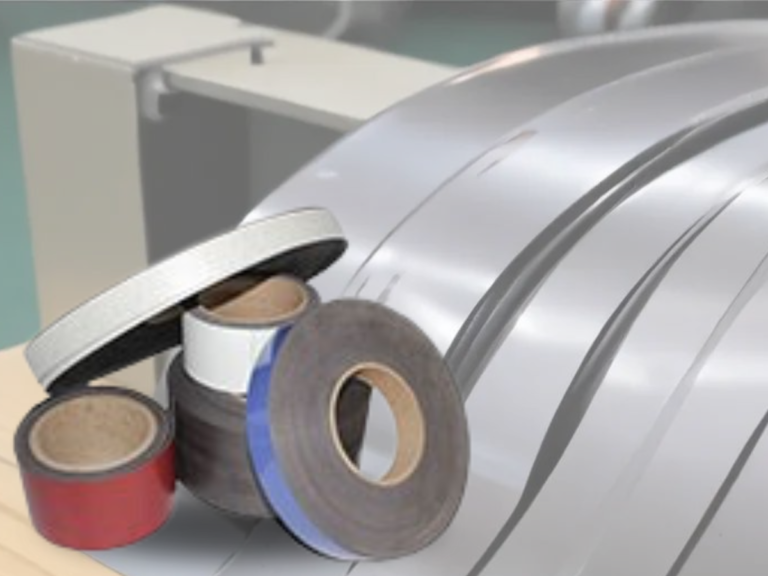

The ability to form and machine this material provides a wide range of potential sizes and shapes as the photograph above illustrates. So, although many standard sizes and shapes are available, this is an excellent magnet when a specific size, shape or configuration is required.

Applications requiring close size tolerances often use these magnets since they can be machined and ground to size. If you need a specific size or shape for a display and you are unsure of which magnet type to use, ceramic magnets are a great option. We carry both stock and custom sizes for all industries and applications.

MAGNETIC FIELD

AlNiCo magnets can be partially demagnetized if like poles of magnets are brought together. Placing individual magnets in contact with ferrous materials can also partially demagnetize them. Care must be exhibited in handling magnetized magnets.

Typical AlNiCo grade 5 ceramic magnet applications require a long magnetic length to pole surface ratio (usually 4:1 or greater) to ensure reliable magnetic performance.

ROCHESTER MAGNET — YOUR SUPPLIER OF QUALITY CERAMIC MAGNETS

When you are looking for magnets for any purpose, you have many options to choose from. At Rochester Magnet, our team of experts can discuss intended usage, industry specifics, and more with you at any time. We pride ourselves on providing high-quality magnets and services to every client.

You can buy ceramic magnets from Rochester Magnet after you receive your free online quote. To start, submit a quote request to talk to our sales team about how we can get you the right product for your application.