How to Choose the Right Neo Magnet for Your Application?

Do you have a project that requires neodymium magnets? Neodymium magnets are known for their incredible magnetic strength and versatility. However, it still requires you

Our high-quality range of flexible magnets strips is being used in various kinds of products and applications. We have rich experience in efficiently converting flexible magnet materials to your specific requirements.

Whether plain or with a set adhesive to scored on a roll or cut pieces, we can provide a great solution for your project.

Download Our Flexible Magnet Capabilities Brochure

Contents |

Whether you are looking for a common size and/or shape or require a completely custom configuration, the process of selecting a flexible magnetic strip starts the same way. The steps below provide a way to specify your magnet or serve as a starting point for a quotation for a custom order. You can order from our “Quick Ship” products in our online store or contact us to help you select the right magnetic strip or tape that works best for you.

It all starts with a few key attributes below:

| Thickness (in) | Magnetic Pull Standard Energy* | “Quick Ship”Standard Energy | Magnetic Pull High Energy* | Standard Length (ft) | Roll Weight3″ Wide Roll (lbs) |

| .020 | 6.2 | 10.1 | 200 | 20 | |

| .030 | 8.5 | Online |

13.8 | 200 | 30 |

| .045 | 9.1 | 14.8 | 200 | 45 | |

| .060 | 11.8 | Online |

19.2 | 100 | 30 |

| .085 | 14.2 | 23.1 | 100 | 42 | |

| .120 | 16.3 | Online |

26.5 | 100 | 60 |

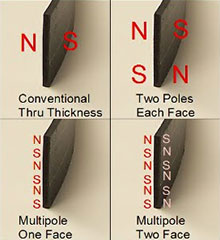

Standard Flexible Magnets are MultiPole Single Faced Magnetized. The image to the right shows this configuration which is applicable to most applications (Multipole One Face).

Other options are available (to the right) for arranging the poles on a flexible magnetic strip. If your project calls for specific magnetization, Rochester Magnet can also accommodate this requirement.

Matched Pole strip is available for magnet face to face applications. The Matched Pole can allow for face-to-face capabilities without any aligning pole issues. Contact us for details. See More at Solutions for Signs and Displays.

Need more strength for already-strong magnetic strips? – You may require a High Energy magnet.

Have a high temperature application or require chemical / solvent resistance? – Nitrile Butile Bonded Magnet may be right for your project.

Offering a stronger level of pull force when compared to a comparable thickness of standard energy flexible magnet, High Energy flexible is highly resistant to demagnetization and free from chipping or cracking, while allowing for ease of fabrication and handling. High Energy flexible is available in adhesive-backed, vinyl laminate or plain material.

Both Standard and High Energy flexible are available in High and Low Modulus Binder. Maximum continuous operating temperatures—175° F (High Modulus), all other 160° F (70° C).Custom Profiles available.High Energy Strip and Sheet are available in a variety of energy levels. Please call so we can discuss your needs and specifications.

Versatile, high quality and economical all describe our Nitrile Butile based products. Rubber bonded strontium ferrite flexible magnets can be bent, twisted and flexed without loss of their high magnetic energy.

Flexible magnet products are produced in three forms:

The following value added options are also available:

Nitrile Butile based magnet has the versatility of accepting several methods of magnetization. The standard methods are conventional, two poles each side, and multiple pole. Custom magnetization patterns are also available making them ideal for low cost position or speed sensing encoders.

These magnets are ideal for high temperature applications and are certified for most automotive applications including inside the engine, transmission, and differential components.

Contact us to learn more and discuss how we can create a product specific to your needs.

| Plain | Adhesive | Laminate |

| No Coating | PSA: Rubber | Vinyl: Matte White |

| No Laminate | PSA: Acrylic | WOWO |

| PSA: Foam | UV Matte White | |

| Vinyl: Colors |

CUT THROUGHThe blade cuts clean through the magnet and the release/lamination to create individual pieces. |

CLEAN SCOREThrough magnet and adhesive, yet not through the adhesive release liner. |

PARTIAL SCOREIncomplete cut through magnet and are separated into individual pieces by bending them at the score line. |

THROUGH LAMINATEAllows separation of the release liner from the adhesive/magnet. |

CUSTOMIn addition, to the straight cut options identified above, we can custom die-cut in standard design or your specific shape. |

When you use our strong flexible magnetic strips, you’ll gain several advantages. High-strength magnetic strips offer the capabilities you need for many different application types and environments, and you can depend on it for critical uses in your industry. Optimize your processes with benefits of our products such as:

At Rochester Magnet, we provide an extensive selection of magnets and offer fast, cost-effective options for quick customization. We’re here to help you get the right products for your operational or functional requirements, and we strive to ensure you have an exceptional customer experience with us. Whether you’re looking for high energy magnet strips, magnetic sheets, or any other type of custom solution, let us work with you to find magnetic systems that work optimally for you. Choose Rochester Magnet, your trusted magnetic solutions provider with the most positive customer reviews in the industry. Please contact us to discuss your specific requirements and get a quote today.

Simply complete and submit the online form below and we’ll review your specs and contact you with any questions.

Do you have a project that requires neodymium magnets? Neodymium magnets are known for their incredible magnetic strength and versatility. However, it still requires you

Flexible permanent magnets come with unique properties, making them important for various industries. From healthcare to automotive, and from consumer electronics to renewable energy, the

Welcome to our comprehensive buyer’s guide on N52 and N35 neodymium magnets. Neodymium Magnet is the powerhouses of the magnetic world! Magnets are fascinating devices

Our magnet experts will help you get exactly what you need – custom or stock – in record time with great quality at a very competitive price.

Ⓒ 2022 - All Rights Are Reserved